The two most common filaments used in home 3D Printing are ABS and PLA

ABS

ABS is short for Acrylonitrile Butadiene Styrene. ABS is one of the main materials in the world of home 3D printing. It is strong, has a degree of flexibility, is easy to machine, is easy to sand and has higher temperature resistance than PLA, having these characteristics make it very useful for engineers, and for mechanical type applications..

It has a petroleum based origin and produces fumes while being heated which are not pleasant or healthy to live or work around and so of course is not food safe. It is recyclable but the high melting temperature of around 230Deg means that it is not as energy efficient as printing with PLA as the print bed also needs to be heated too. The main issue when it comes to 3D Printing is the fact that ABS expands and shrinks during the process of being heated and cooled down again.

The shrinkage in particular can be problem because it causes 3D prints to curl up while cooling too quickly, which is called warping. To counter this, ABS has to be printed on a heated build plate and preferably in an enclosed, heated build chamber so it stays warm during printing and can cool down slowly when printing is done. In general this means that printers which can print in ABS are more expensive than those that solely print in PLA. There also seem to be less colours available in ABS when compared to PLA

ABS is dissolvable in acetone this is the same chemical used in nail polish remover. Acetone can be used to smooth the surface of a 3D Print by first of all sanding the print and then wiping it with acetone, this will dissolve the outer layer, essentially smoothing it by reducing the visibility of layers in the print, one thing to be aware of is that ABS prints which start with a matte finish will have a shiny glossy finish on completion of the process.

If there will be a significant period of time between prints then it is important to store the ABS in a sealed non humid location , a week or too should not have a significant detrimental effects but long term exposure to a humid environment can affect both the printing process and to the quality of finished parts. ABS that has absorbed moisture will tend to bubble and spurt from the tip of the nozzle when printing, his reduces the visual quality of the part, the part accuracy, strength and also introduces the risk of either stripping or clogging in the nozzle.

PLA

PLA (Polylactic Acid is completely different to ABS. It is strong, and more rigid than ABS but sometimes be more difficult to work.It has a lower thermal resistance and so a finished part could warp if left iclose to a window on a very hot day. Printed objects will generally have a glossier look and feel than ABS although it too can be sanded and machined to give a smooth finsih. It is predominantly used for display items rather than mechanical/functional products.

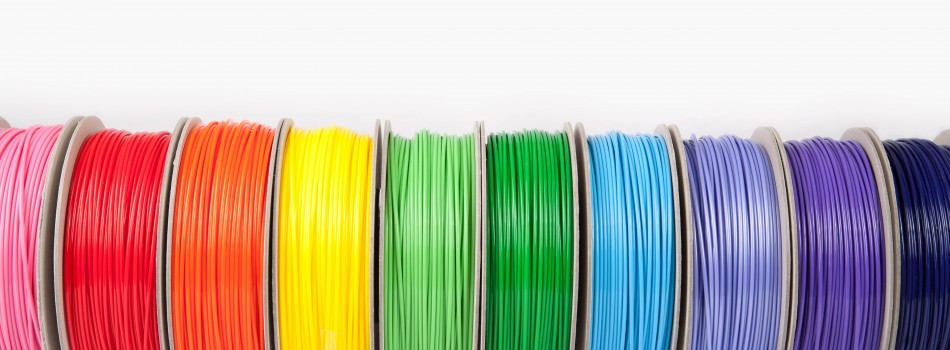

It is manufactured from corn starch or sugar cane and is also biodegradable, because of this it does not give off unpleasant or harmful fumes . It is also more energy efficient when it comes to 3D Printing as the melting point (190-210Deg) is lower than ABS and it does not need a heated bed, if the printer has the capability though many people use a thin layer of glue and heat the bed to around 60Deg to try and eliminate any warping. PLA comes in much wider range of colours and is a popular choice for household or decorative items.

PLA is considered food safe by many but if you do a search on the internet you will find many conflicting opinions and theories! The best information we have found states that :

“The study found that PLA is Generally Recognized As Safe (GRAS) when used in contact with food. Their summary concluded that PLA releases a small amount of lactic acid into foods. Lactic acid is a common food ingredient, that is even found in breast milk. They estimated that the amount of lactic acid people would consume from PLA to be about 700 times less than the lactic acid intake of breast-fed infants.

Many 3D printer hot ends contain materials that are certainly not food safe. So if you are not using an all stainless steel hot end, trace amounts of nasties could find their way from your printer hot end, into your model and eventually into your food.

Most PLA is coloured. So other additives have been added to your PLA If you are printing things that contact foods, you should stick with ‘virgin’ or ‘natural’ PLA.

It is going to be near impossible to keep your printed objects clean. 3D prints are covered with nooks and crannies. These little pores, when filled with food are a fertile breading ground for bacteria that could give you a nasty case of food poisoning. You should consider prints that come in contact with food as disposable, and should probably throw them away after a single use.

http://reprage.com/post/36869678168/is-3d-printed-pla-food-safe/

Our Opinion

At CADEC since we can not guarantee with any kind of formal certification that the parts we print are food safe . We take the stance that non of our prints can be classed as officially food safe.

Speciality Filaments

As more and more people become involved with 3D Printing the demand for alternate materials to the main two is ever increasing. 3D Printer manufacturers and Filament manufacturers are continually developing and releasing new materials of people to try. Below are just a few of the many filaments on the market:

Soft PLA/ Bendlay/Ninjaflex, also known as ‘flexible’ PLA, is useful for printing rubber-like parts that can bend or flex.

LAYWOO-D3 is a wood-like 3D printing material that gives 3D printed objects the look and feel of fiberboard. It also imbues parts with other wood-like attributes, such as the ability be cut, painted, and sanded. It is also possible to give parts printed in LAYWOO-D3 a simulated alternating light/dark wood-grain appearance by varying the temperature during printing

LAYBRICK is a 3D printing material that gives parts the look and feel of grey stone while retaining the resiliency of plastic, making it ideal for landscape and architectural designs. Anything made with LAYBRICK can be painted and sanded. In the lower range of 165°C to 190°C, the print will come out mostly smooth, whereas with higher temperatures it will begin to have a more pitted, sandstone-like texture.

Nylon is a versatile 3D printing material which prints as a bright natural to white with a translucent surface, and can absorb color added post process with most common, acid-based clothing dyes. Unprinted Nylon is extremely sensitive to moisture, so taking drying measures during storage and immediately prior to printing is highly recommended for optimal results.

Colorfabb –Bronze Fill 3D printing with metal on your own desktop 3d printer! This amazing one of a kind filament will allow you to print with actual bronze at home! Straight from the printer parts look almost laser sintered with a matte finish.

With a bit of sanding and polishing the bronze particles will start to shine and shimmer unlike any 3d printing filament you have seen before. The weight of the material is something special, about 3 times heavier then our regular PLA/PHA.